Product List

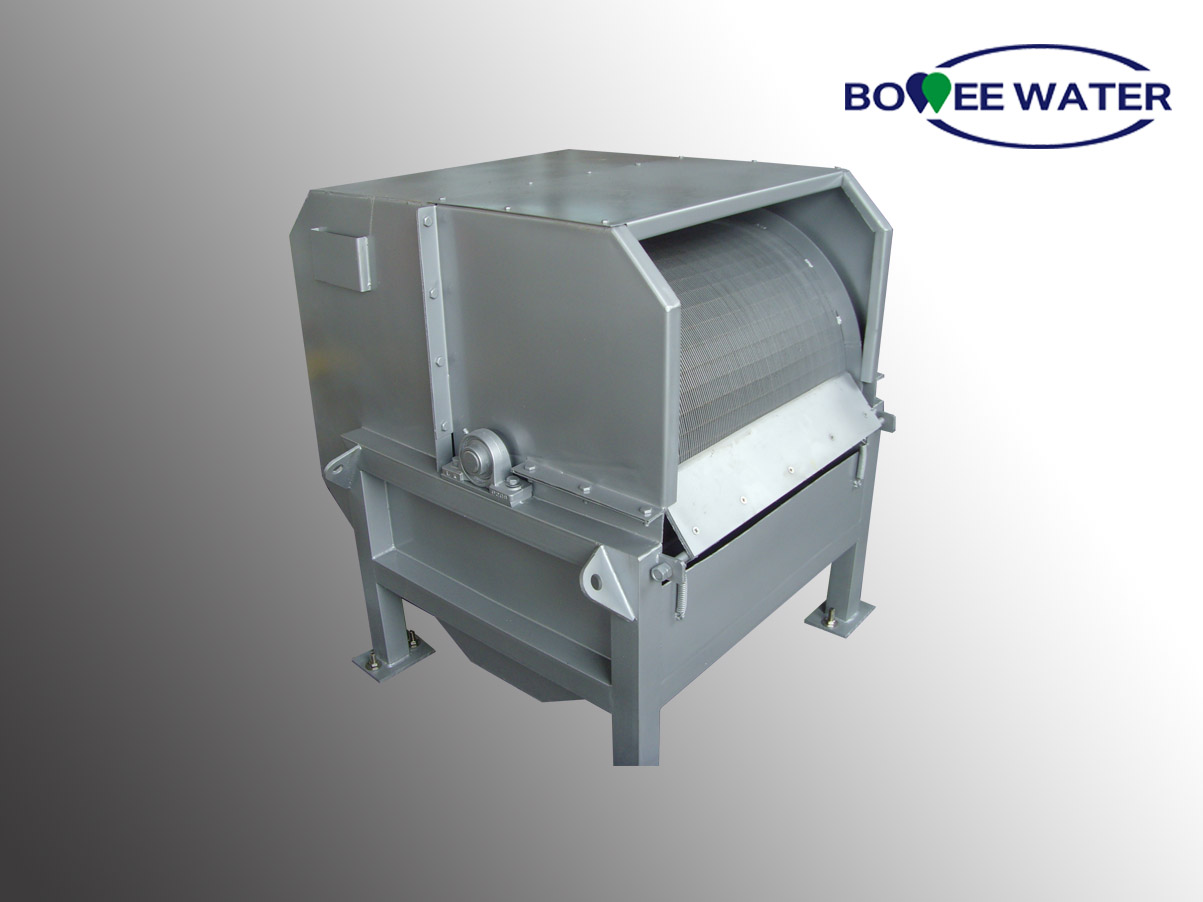

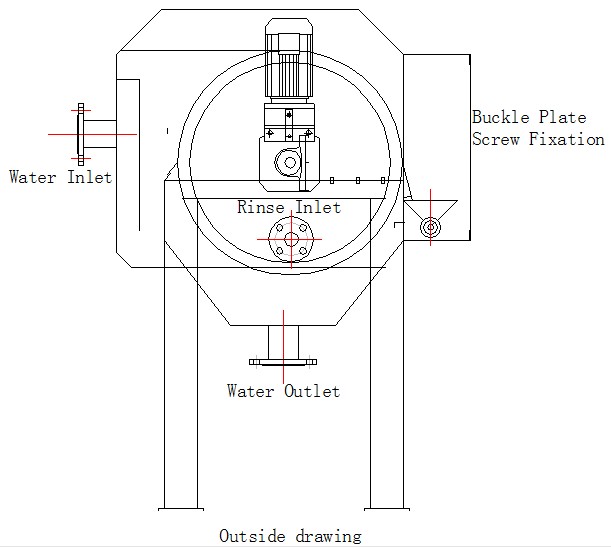

The External Feed Rotary Drum Screen is a machine for the fine screening of sewage coming from industrial or civil purification plants, or for the screening of process waters coming from industrial transformation plants.

Specifications:

Capacity: 0-560m3/h

Dimension: Customized

Material: SS304, SS316 or Customized

Opening type: wedge wire or perforated

Opening size:0.15-5mm

Motor brand: First-class motor, Nord or SEW is optional

-

Description

The External Feed Rotary Drum Screen is a machine for the fine screening of sewage coming from industrial or civil purification plants, or for the screening of process waters coming from industrial transformation plants.

The External Feed Rotary Drum Screen is used in purification plants or process water treatment plants, where it is necessary to screen a large amount of fluid, i.e. fluids coming from steam raised pipelines. It is possible to install such a machine in aerial channels or in narrow spaces thanks to its limited dimensions in relation to the obtainable capacities.

-

Applications

· Civil purification plants

· Paper Mills

· Food Industry

· Chemical Industry

-

Technical parameters

Model

Screen size

(mm)

Mesh size

(mm)

Max capacity

(m3/h)

Dimension

(mm)

Power

(kW)

Material

BWSEF-300

Φ300*500

0.15-5

5-50

760*700*1200

0.55

SS304,SS316

BWSEF-400

Φ400*600

0.15-5

8-90

860*800*1300

0.55

SS304,SS316

BWSEF-500

Φ500*750

0.15-5

12-140

1050*900*1500

0.75

SS304,SS316

BWSEF-600

Φ600*900

0.15-5

17-200

1160*1000*1500

0.75

SS304,SS316

BWSEF-700

Φ700*1000

0.15-5

23-280

1260*1100*1600

0.75

SS304,SS316

BWSEF-800

Φ800*1200

0.15-5

30-360

1460*1200*1700

1.1

SS304,SS316

BWSEF-900

Φ900*1350

0.15-5

40-450

1600*1300*1800

1.5

SS304,SS316

BWSEF-1000

Φ1000*1500

0.15-5

50-560

1600*1300*1800

1.5

SS304,SS316

-

Advantages

1. The material is high-strength and corrosion-resistant stainless steel; Less used field area; Convenient construction; It can be directly fixed with expansion bolts without channel construction; Inlet and outlet water can be connected with pipes.

2. The screen will not be blocked by waste solid because the machine is inverted trapezoid cross section

3. The machine is controlled by adjustable-speed motor, which can maintain optimum working condition according to water flow.

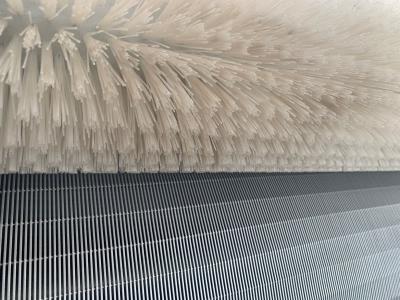

4. Special washing device can brush away the impurities on the surface of screen, after twice internal brush, it will achieve the best cleaning effect.

-

Related Products